Static Dissipative Acrylic Data Sheet – ESD/Cleanroom Properties for Acrylic Material

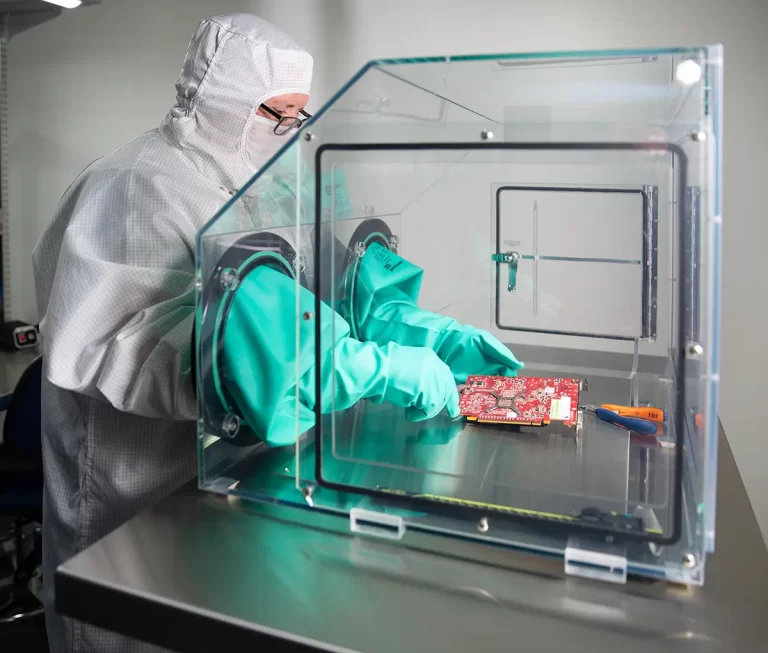

TDI Static Dissipative Desiccators and Gloveboxes

Static Dissipative Acrylic Data Sheet for Material used on our Desiccators & Gloveboxes

FEATURES AND BENEFITS:

- Cannot be tribocharged when properly grounded.

- Prevents build-up of static charge and accumulation of harmful contamination.

- Electrostatic decay in less than 0.05 second per Federal Test Standard 101C, Method 4046.1*. Results in rapid static dissipation without arcing.

- The surface resistivity of 106 – 108 ohms per square. Provides ESD control in a wide range of applications.

- Permanence in static dissipation performance. Avoids high maintenance cost of periodic application of temporary topical anti-stats.

- Amine free, humidity independent and does not outgas under normal operating conditions.

- Excellent optical properties. C-300 surface provides excellent clarity for optimum use of available light.

- Superior chemical resistance. Reduces risk of solvent and chemical damage to the static dissipative surface.

PRECAUTIONS:

- Acrylic plastic is a combustive thermoplastic. Avoid exposure to flame and excessive heat. Observe fire precautions appropriate for comparable forms of wood and paper.

- Clean with soap and water. Do not use abrasives. Avoid inappropriate contact with solvents.

Static Dissipative Acrylic for ESD and Cleanroom Applications

Typical Physical Properties (Typical but not Guaranteed for 0.25-inch Material)

| PROPERTY | TEST METHOD | UNITS | AC-300 ACRYLIC |

| PHYSICAL | |||

| Specific Gravity | ASTM D-792 | – | 1.19 |

| Pencil Hardness | ASTM D-3363 | Hardness Scale | 5H |

| MECHANICAL | |||

| Tensile Strength | |||

| Ultimate | ASTM D-638 | psi | 10,000 |

| Elongation | ASTM D-638 | % | 4.5 |

| Tensile Modulus | ASTM D-638 | psi | 400,000 |

| Flexural Strength | ASTM D-790 | psi | 16,500 |

| Flexural Modulus | ASTM D-790 | psi | 475,000 |

| Compressive Strength | ASTM D-695 | psi | 18,000 |

| Izod Impact Strength | ASTM D-256 | ft-lb/inch of notch | 0.4 |

| THERMAL | |||

| Deflection Temperature (264 psi Load) | ASTM D-648 | F | 205 |

| Vicat Softening Point | ASTM D1525 | F | 239 |

| Maximum Continuous Service Temperature | – | F | 170 |

| Coefficient of Thermal Expansion | ASTM D-696 | in/in/F | 4.0 x 10 |

| Coefficient of Thermal Conductivity | Cenco-Fitch | BTU/hr-fz F/in | 1.3 |

| FLAMMABILITY | |||

| Horizontal Burn (Flame Spread) | ASTM D-635 | in/min | 1.1 |

| UL Rating | UL Classification | UL94 | 94HB |

| OPTICAL | |||

| 3mm Transparent Clear Transmittance – Total | ASTM D-1003 | % | 9 |

| Haze | ASTM D-1003 | % | 94HB |

| ELECTRICAL | |||

| Surface Resistivity | ASTM D-257 | ohms/sq. | 106-108 |

| Electrostatic Decay | FTS 101C, Method 4046.1 | sec | Less than 0.05 |

Federal Test Standard 101C, Method 4046.1 as described in EIA-541, Appendix F, Measurement of Electrostatic Decay Properties of Dissipative Planar Materials.

Chemical Resistance ASTM D-543(Samples immersed in the specified chemicals for 24 hours at room temperature and visually examined.) | ||

| CHEMICAL | SURFACE ATTACK | VISUAL EVALUATION |

| De-Ionized Water | None | Clear |

| 30% Sodium Hydroxide | None | Clear |

| 30% Sulfuric Acid | None | Clear |

| 30% Nitric Acid | Slight Pitting | Clear |

| 48% Hydrofluoric Acid | Severe Attack | White, Rubbery |

| Methanol | Slight | Hazy |

| Ethanol | None | Clear |

| Isopropyl Alcohol | None | Clear |

| Acetone | Severe Pitting | Clear |

| Methylene Chloride | Sample Dissolved | Sample Dissolved |