Tweezers Materials Selection Guide – All Materials

Guide to choosing the best tweezers for your applications.

METALS

“SA” Stainless Anti-Magnetic High Precision

Made of low carbon austenitic steel. Contains chromium as well as nickel and molybdenum as additional alloying elements. Further, stainless anti-magnetic tweezers are non-magnetizable with good corrosion resistance to most chemicals, salts and acids. For electronics assembly and especially labs in mild aggressive chemical applications.

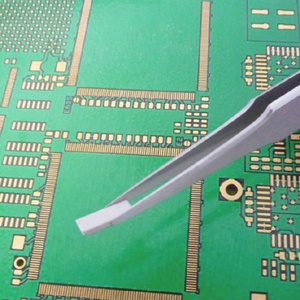

High precision stainless anti-magnetic tweezers are perfectly balanced, offering fine tip symmetry for precision work. Tip edges are polished to provide a non-scratch and also anti-glare finish.

“SA-I” Stainless Anti-Magnetic Precision

Stainless anti-magnetic with precision tip symmetry and balance with good corrosion resistance to most chemicals and acids. Engineered to meet the requirements for general electronics assembly, labs, clean rooms as well as circuit board repair and rework.

High Quality, Low Cost!

C-series industrial grade stainless anti-magnetic. Tip dimensions are approximate, making these tweezers an ideal economical choice when not working under a microscope.

Good corrosion resistance to most chemicals, salts and acids.p

PLASTICS

“TD”® Static Dissipative Polymer High Precision

“TD”® static dissipative polymer tweezers are for the most critical ESD applications. Less than 40V ESD threshold Class 0 CDM Compliant.

“TD”® Polymer tweezers are very hard and rigid and because of this offer very low moisture absorption. Boasting a high heat capability of 200°C (for continuous use) to 230°C (when used for a short time). Excellent chemical resistance to organic solvents, oils, grease, fuels, acids and alkalis. Especially ideal for handling of EOS/ESD sensitive components and handling of components during thermal, chemical and soldering processes.

“TD”® Polymer tweezers are extensively ESD tested including Transient Current Discharge analysis for Class 0 CDM compliance.

“CP” Conductive PEEK High Precision

ESD safe conductive material with a surface resistivity of 105 Ohms/sq. PEEK (polyetheretherketone) is very hard and rigid with very high wear resistance. Boasting a high heat capability of 260°C (for continuous use) to 300°C (when used for a short time).

Excellent resistance to most chemicals and aggressive agents. Applications include handling of components in cleaning, chemical, and especially assembly processes in many industries.

“CF” Conductive CarboFib High Precision

ESD safe conductive material 102 Ohms/sq. CarboFib tip tweezers are temperature resistant 130°C (for continuous use) to 190°C (when used for a short time). This material offers very high rigidity and low friction with excellent wear and abrasion resistance.

Moderate chemical resistance, although not resistant to strong acids, alkalis and hot water or steam. Typical applications for CarboFib tweezers include handling and positioning of scratch-sensitive electronic components and devices.

CERAMICS

“KD”® Static Dissipative Black Ceramic High Precision

“KD”® static dissipative ceramic tweezers are for the most critical ESD applications. Less than 40V ESD threshold Class 0 CDM Compliant.

ESD safe static dissipative material. A superior combination of high strength (from zirconia) and high hardness (from alumina). No open porosity, very hard surface with good abrasion and wear resistance. Excellent thermal properties and high temperature stability. Extreme corrosion resistance, nearly chemically inert. Typical applications include handling of EOS/ESD sensitive components and handling of components during thermal, chemical and soldering processes. Generally used when very rigid tips are required.

“KD”® ceramic tweezers are extensively ESD tested including Transient Current Discharge analysis for Class 0 CDM compliance.

CUSHION HANDLES

“DVH” Vinyl Handle Coating Cushion Grips

TDI offers tweezers with ESD static dissipative “DVH” cushion grips. These grips provide reduced finger stress and superior operator comfort when working continuously with small parts.

Precision tweezers are made of the highest quality materials, for example our low carbon, stainless anti-magnetic. The tips are perfectly balanced offering fine tip symmetry for precision work. Additionally, metal tip edges are polished to provide a smooth and anti-glare finish.

We engineer our tweezers to meet the requirements for electronics assembly, labs, clean rooms as well as circuit board repair/rework.

Available for most tweezer styles, metal and fiber replaceable tip. Static dissipative with a surface resistivity of 109-1011 Ohms/sq.

TEFLON COATINGS

Teflon coating is a must when working with sensitive parts. Non-scratching Teflon is an alternative to replaceable tip tweezers. Most commonly utilized on wafer handling tweezers.

Teflon coatings are available for all metal tweezers upon request. Coat entire tweezers in order to prevent scratching of delicate parts.

Available in 1.5,. thickness only. Minimum 12 per style.